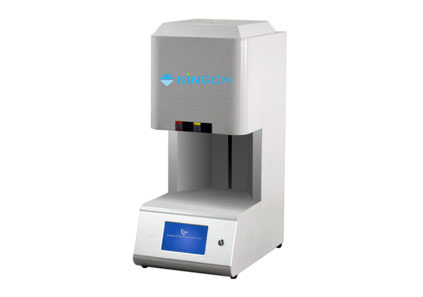

Product Features:

(1) Environmental protection, lifting without noise.

(2) Touch screen control is easier and faster.

(3) The furnace adopts a circular structure, and the heating elements are evenly distributed on the circumference, making the temperature field more reasonable and uniform.

(4) The furnace body adopts a bottom-loading automatic lifting structure, which is conducive to safe picking and placing of sintered patterns, especially for high-temperature sintering of zirconia dentures, with good consistency and high permeability.

(5) You can choose the function of automatically running the program at a fixed time, which is more energy-saving. There are 15 solidification programs, which can be selected arbitrarily.

(6) The furnace is made of high-purity imported refractory fiber, which will never change the color of the crown.

Technical Parameters:

|

Product Name |

Lifting Zirconia Sintering Furnace |

|---|---|

|

Product Model |

CY-T1700-F |

|

Hearth Model |

Bottom feeding, lifting type |

|

Display Modo |

Touch Screen |

|

Max. Temp. |

1700 ℃ |

|

Working Temp. |

≤1650 ℃ |

|

Heating Rate |

Suggest 0-20℃/min |

|

Heating Zone |

Single heating zone |

|

Height of Heating Zone |

120mm |

|

Diameter of Heating one |

120mm |

|

Temp. Control Accurancy |

±1℃ |

|

Heating Modo |

Four sides heating |

|

Sealing Method |

Pedestal furnace door |

|

Temp. Curve |

30 segments of "time-temperature curve" can be set arbitrarily |

|

Stored Curve |

Multi-day temperature curves can be stored in advance |

|

Over Temperature Alarm |

YES |

|

Overcurrent Protection |

YES |

|

Disjunction Indication |

YES |

|

Temp. Measure Element |

Type B thermocouple |

|

Heating Element |

1800 Pure silicon molybdenum rod |

|

Hearth Material |

Alumina fiber |

|

Rated Voltage |

220V,AC,50-60 Hz |

|

Rated Power |

2 Kw |

|

Aftersales Service |

1 year warranty whole life repair |

|

Package |

Processed wooden box |